Effektivitet og innovation går hånd i hånd hos VVS Aarhus. Deres løsninger sikrer, at kunderne altid får den bedste service og de mest moderne teknologier inden for VVS-branchen.

Forny dit hjem med topmoderne VVS Viborg teknikker

Er du træt af det gamle VVS i dit hjem? Opgrader med topmoderne VVS Viborg teknikker og skab et mere effektivt og moderne rum. Lad eksperterne hjælpe dig med at forny dit hjem i dag.

Hvorfor VVS Randers er afgørende for din boligsikkerhed

VVS-systemet i din bolig er livsvigtigt for både din komfort og sikkerhed. VVS Randers sørger for at holde dine installationer i topform, så du kan føle dig tryg i dit hjem.

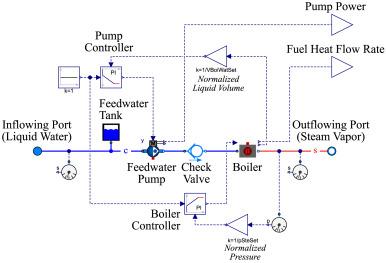

VVS Næstved: Hvordan teknologi forbedrer effektiviteten

VVS Næstved har succes med at implementere ny teknologi for at forbedre deres effektivitet. Ved at automatisere processer og integrere data har de skabt en mere strømlinet arbejdsflow. Læs mere om deres innovative tilgang.

VVS Køge: Komplet guide til vedligeholdelse og reparation

VVS Køge tilbyder en komplet guide til vedligeholdelse og reparation af dit VVS-udstyr. Uanset om det er et stoppede afløb eller en utæt vandhane, kan du regne med professionel hjælp fra VVS Køge. Opdag alle de nyttige tips og tricks til at sikre, at dit VVS-udstyr fungerer optimalt.

Udforsk VVS Silkeborg: Branchens bedste standarder og praksis

Dyk ned i verdenen af VVS-arbejde og opdag de bedste standarder og praksisser hos Udforsk VVS Silkeborg. Lad dig inspirere af branchens fineste håndværk og ekspertise.

Værdien af pålidelig VVS i VVS Horsens

Når det kommer til VVS i Horsens, er pålidelighed nøglen til succes. Med pålidelig VVS kan du være sikker på, at dine installationer fungerer problemfrit og effektivt. Værdien af pålidelig VVS kan ikke undervurderes.

Avanceret VVS teknologi i VVS Aalborg

VVS Aalborg tager skridtet ind i fremtiden med avanceret VVS-teknologi. Fra intelligente termostater til energieffektive varmeinstallationer, firmaet satser på innovative løsninger for et mere bæredygtigt og komfortabelt hjem.

Sådan vælger du en pålidelig VVS Roskilde udbyder

Når du skal vælge en pålidelig VVS Roskilde udbyder, er det vigtigt at se på deres erfaring, kundeanmeldelser, og certificeringer. Sørg for at få flere tilbud og vælg den bedste til dine behov.

Moderne VVS løsninger og service i VVS Herning

Moderne VVS-løsninger og service i VVS Herning sætter standarden for effektivitet og kvalitet. Med et dedikeret team af erfarne fagfolk er dine VVS-behov i trygge hænder. Lad os skabe komfort i dit hjem med innovative løsninger.

Den komplette guide til VVS Odense tjenester

Dyk ned i den komplette guide til VVS Odense tjenester og få indblik i alt, hvad du behøver at vide om VVS-installationer og -reparationer i Odense. Lad os hjælpe dig med at finde den rette løsning til dine VVS-behov.

Økonomiske og miljømæssige fordele ved VVS Vejle

Der er mange økonomiske og miljømæssige fordele ved at vælge en professionel VVS service i Vejle. Med fokus på energieffektivitet og bæredygtige løsninger, kan VVS Vejle hjælpe med at spare penge på både kort og lang sigt.

VVS Fredericia: Sikkerhedsstandarder og certificeringer

I en verden fyldt med teknologiske udfordringer er VVS Fredericia et pålideligt firma, der prioriterer sikkerhedsstandarder og certificeringer. Med fokus på kvalitet og professionalisme sikrer de tryghed og tillid hos deres kunder.

Trends og tips inden for VVS Kolding

Opdag de nyeste trends og nyttige tips inden for VVS i Kolding. Fra energibesparende løsninger til stilfulde designvalg – få inspiration til dit næste VVS-projekt her.

VVS Esbjerg: Alt du skal vide om installationer og service

VVS Esbjerg er din go-to for alt inden for installationer og service. Uanset om det er blikkenslagerarbejde eller VVS-opgaver, så kan du regne med deres ekspertise og professionalisme. Læs med her for at få alt at vide om deres tjenester.

De bedste VVS praksisser for ældre ejendomme i VVS Helsingør

Når det kommer til ældre ejendomme, er det vigtigt at implementere de bedste VVS praksisser for at sikre optimal funktion og lang levetid. VVS Helsingør tilbyder professionelle løsninger til at opretholde ældre bygningers installationer.